Our latest news and views English

Underpinned by our Scandinavian design heritage, we bring you regular stories about architecture and interiors, exploring natural materials, acoustics, and the creation of safe and harmonious environments.

We take a look back at the origins of Gustafs to learn more about the people, processes and projects which have shaped its past. It’s a story that starts with steam and sawmills, that advances through the decades harnessing industrialisation and manufacturing expansion, while always maintaining a strong carpentry tradition, combined with the essence of Scandinavian design.

Gustafs started life in the village from which it takes its name, in the county of Dalarna, around three hours’ drive from Stockholm. It is surrounded by forests, the natural commodity that would bring the place prosperity, particularly as the value of timber for industrial uses such as construction began to grow in the nineteenth century.

A local man with a steam boat named Axel Wikstrom saw an opportunity to harness the power of steam to process the timber. Before that, waterfalls had to be ‘tamed’ to do the job. He picked up his steam engine and transported it to the village. There, he built a wooden shed in which he installed the boat’s steam engine – Gustafs’ first industrial facility one could say, albeit on a small scale.

Now a mobile energy source could power a sawmill, which could be located near to the forest and also close to transport interchanges. When the railway arrived in Gustafs in 1881, it cut the time to reach Stockholm from five days by horse and carriage to just five hours by train. This signalled a great opportunity to export far and wide to countries including the UK.

By the turn of the twentieth century, Wikstrom had teamed up with a business partner and invested in a cutting blade and a planer. This allowed mouldings for picture frames to be manufactured, as well as for architectural details, such as window frames and architraves. This is where Gustafs’ heritage of processing timber and planing crafted, highly detailed pieces of wood dates back to.

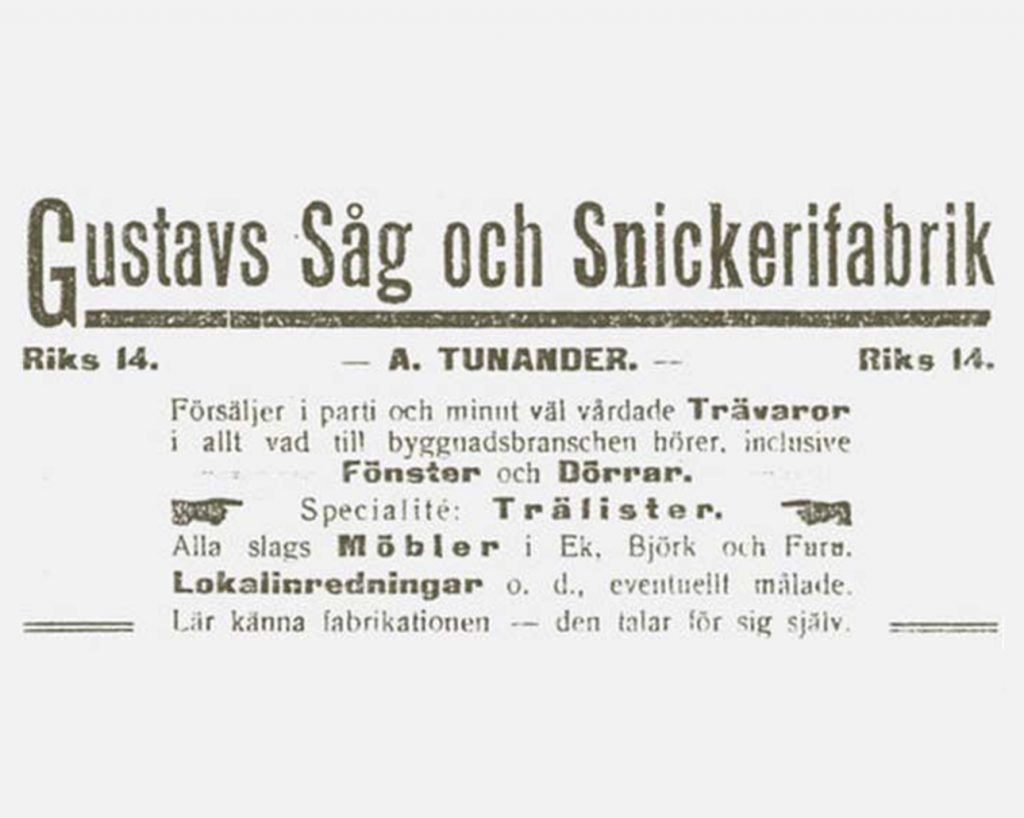

The next person who would come to shape Gustafs’ history is Andreas Tunander, a builder who moved to the village and bought the business in 1913, following a series of mergers and bankruptcies. When electricity reached Gustafs in 1918, it industrialised the saw milling and planing process further, although it took a while before the saw could run on electricity, as initially the electric power caused it to run too fast!

This, combined with the carpentry skills of a local workforce whose hearts were in traditional woodcrafting, saw the business go from strength to strength. The region had become a centre for picture framing manufacturing and assembly, with Gustafs’ mouldings sold to local framing factories.

Ever the entrepreneur, in the 1920s Tunander bought a neighbouring furniture factory which meant Gustafs could go on to supply commercial interiors, something for which the company is still known today. The business also started a collaboration with Kooperativa Förbundet (the Swedish cooperative consumer group), working on standardised, mass produced interiors for their commercial premises. Eventually their own picture framing business, Gustafs List, was established too, in keeping with the local expertise.

Although the second world war brought difficult times, the business was able to continue trading, thanks to its expertise in decorative mouldings. In an interview, Andreas Tunander explained:

“The crisis has led to a certain stagnation in business interiors… Despite the times, the moulding planer is doing quite well. Although 1940 was a dark year, this year is much better. People get married and take photos and buy paintings – and they need nice frames for these.”

Andreas Tunander, Gustafs

It was also during the 1940’s that Gustafs started supplying interiors for ships, which led to research and development in the field of fire safe wood interiors. Fast forward to the 1960s and there were many reasons to celebrate. It was 50 years since Tunander had successfully re-launched the business, and thanks to the association with Kooperativa Förbundet – which had become something of a popular movement – business was booming. In 1969, a new, state-of-the-art factory was unveiled.

Looking further ahead to the 1980s, one of the most memorable projects was a luxury hotel in Baghdad, Iraq, called the Royal Tulip Al Rasheed Hotel. For a while, the entirety of Gustafs’ production line was involved in the manufacturing of the interiors for the hotel’s 17 floors; crafting 1800 doors and wall panels in a walnut finish.

As well as this project in the Middle East, Europe became a key market with strong sales in France and Switzerland. And closer to home, Gustafs had begun an ongoing collaboration to supply wood interiors and furniture to one of Sweden’s largest banks.

In 1986, the Fohlström Group acquired the company, becoming Sweden’s strongest wood processing group within interiors for public and commercial environments. It was also around this time that fire-certified panels became a core part of the offering.

During the 1990’s and 2000’s, Gustafs saw several changes in the structure of its ownership, alongside increased investment and focus on growing the expertise in acoustics, fire safety and design. The company continued to develop their product offering, moving away from furniture and focusing instead on interior cladding panels.

In 2005, Gustafs was involved in creating one of the best-known public spaces in Sweden, the parliament building or ‘Riksdag’. Birch wood veneer panels were used to clad the walls and ceilings of the auditorium, modernising the interior and giving a sense of the Swedish midsummer.

In terms of international projects, the Qatar National Convention Centre with its distinctive three-dimensional acoustic wall is a particular milestone, inaugurated in 2013. Continuing to innovate, also in 2013, both the pioneering Gustafs Linear System of slatted timber panels for interior cladding and the invisible Nano acoustics were introduced.

Today, Gustafs Scandinavia is supplying its multiple ranges of wood panel products to interior projects around the world, whilst staying close to its origins. The business is firmly rooted in the village of Gustafs and ensures that carpentry and craftsmanship remain a foundation – and a source of pride – in this thriving company’s culture.