Gustafs sound absorbers – Sounds Beautiful

In this section we will describe and explain five types of sound absorbers. How they work, their unique properties and how they relate to Gustafs sound absorbers

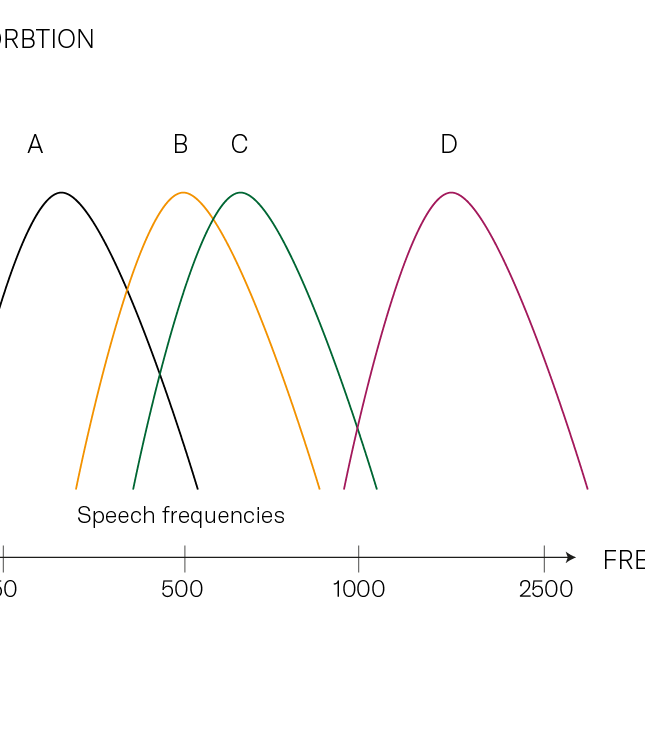

A. Sub Resonance absorbers (Membrane)

B. Mid Resonance absorbers, Panels (Helmholtz)

C. Mid Resonance absorbers, Linear Rib (Helmholtz)

D. Nano absorbers (Nano + Helmholtz)

E. Porous absorbers

The illustration shows the approximate frequency bands in which the various types of absorbers have their peak performance.

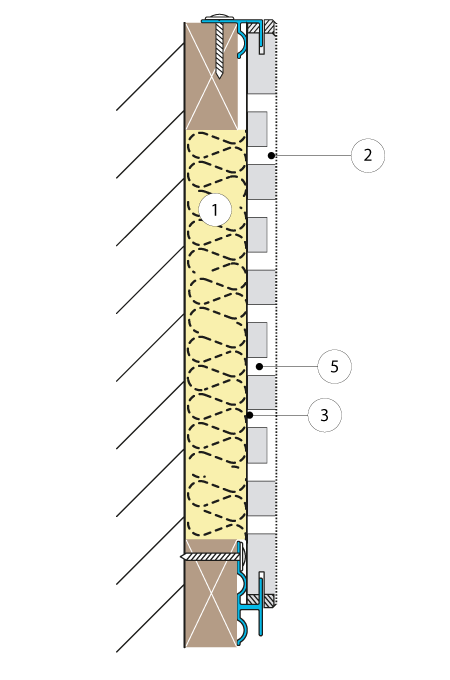

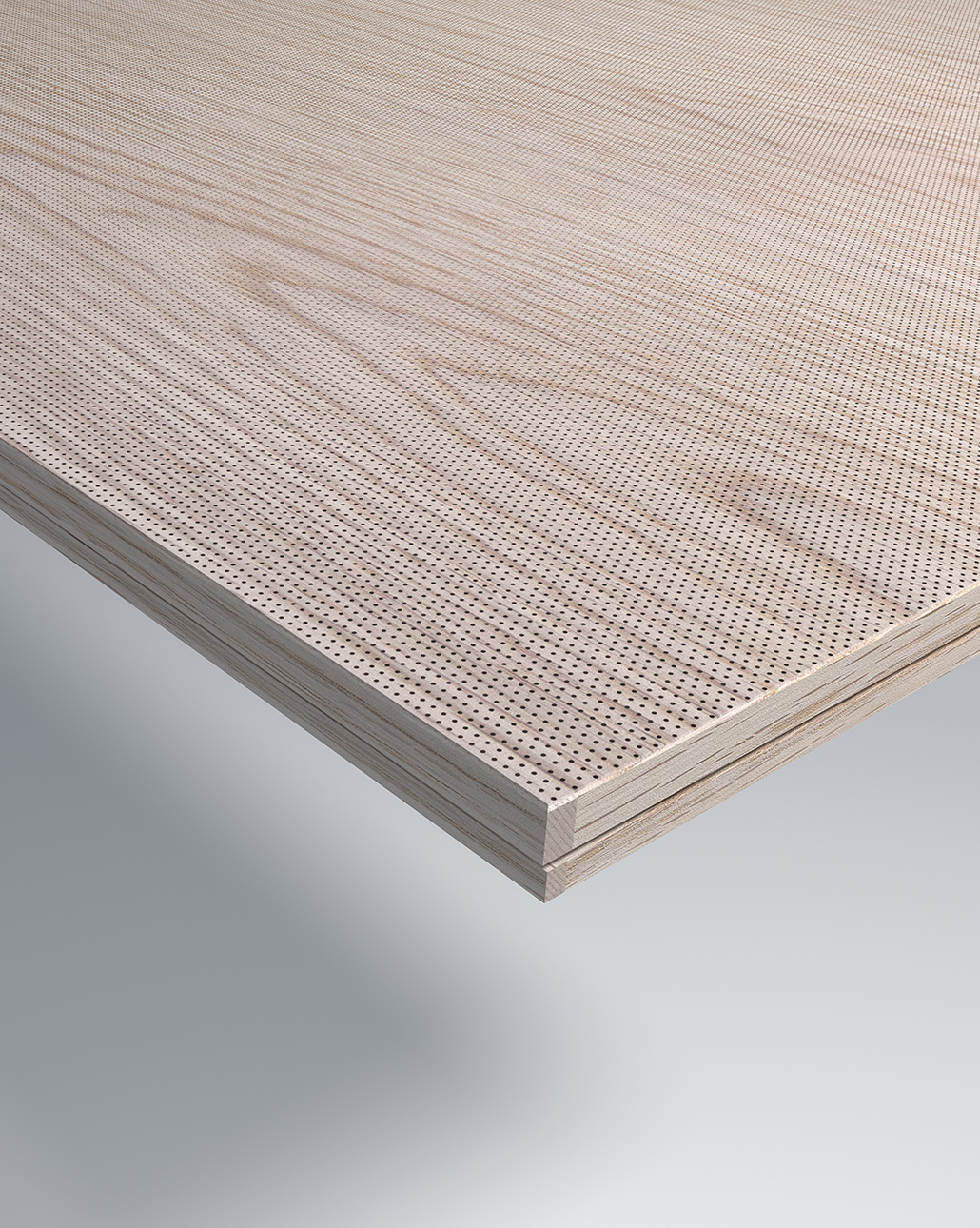

B. Mid Resonance absorbers, Panels (Helmholtz)

Helmholtz absorbers are used to reduce mid frequencies. The Helmholtz construction contains a “chamber” (1) (the void) which is connected to the room trough a “neck” (2) (the perforation hole). The air in the neck is influenced by sound and puts the air in the chamber in resonation, which transforms sound energy into heat energy. The sound absorption increases if the distance to the wall, and by that the chamber/void is enlarged. Helmholtz absorbers do work over a shorter interval of frequencies, but this can be improved by filling the void with a porous mineral wool (1) and putting an air permeable felt (3) directly behind the “neck”.

RECOMMENDED GUSTAFS PRODUCTS

Panels with round perforations

RP8- Barcode

RP8-C10

RP8-C20

Bespoke perforations

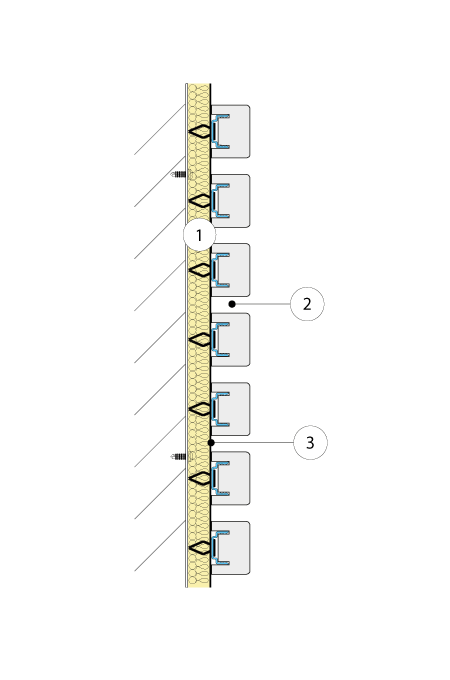

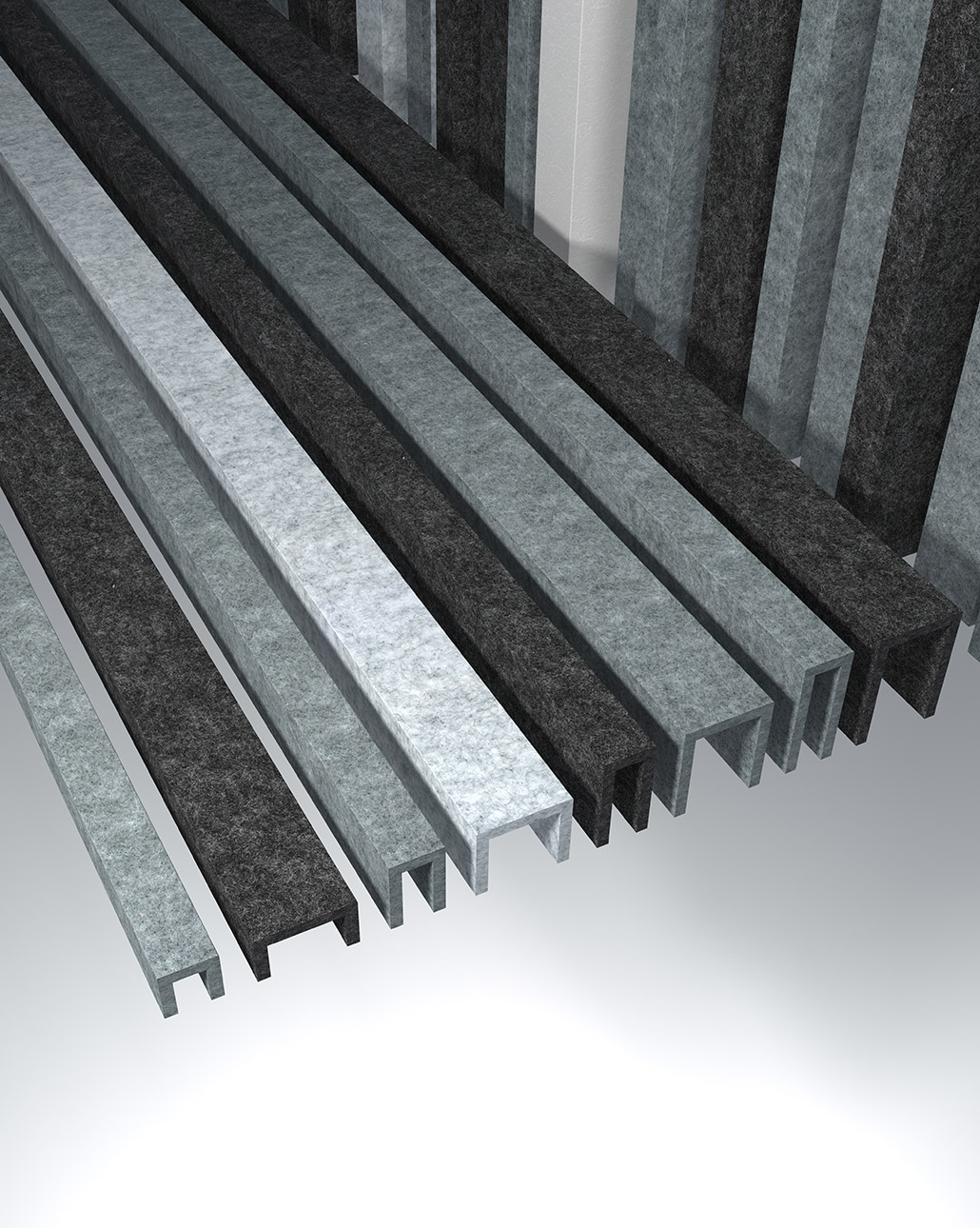

C. Mid Resonance absorbers, Linear Rib (Helmholtz)

Helmholtz absorbers are used to reduce mid frequencies. The Helmholtz construction contains a “chamber” (1) (the void) which is connected to the room trough a “neck” (2) (the spacing between linear ribs). The air in the neck is influenced by sound and puts the air in the chamber in resonation, which transforms sound energy into heat energy. The sound absorption increases if the distance to the wall, and by that the chamber/void is enlarged. Helmholtz absorbers do work over a shorter interval of frequencies, but this can be improved by filling the void with a porous mineral wool (1) and putting an air permeable felt (3) directly behind the “neck”.

RECOMMENDED GUSTAFS PRODUCTS

Linear Rib-R

Linear Rib-S

Linear Stripe XL

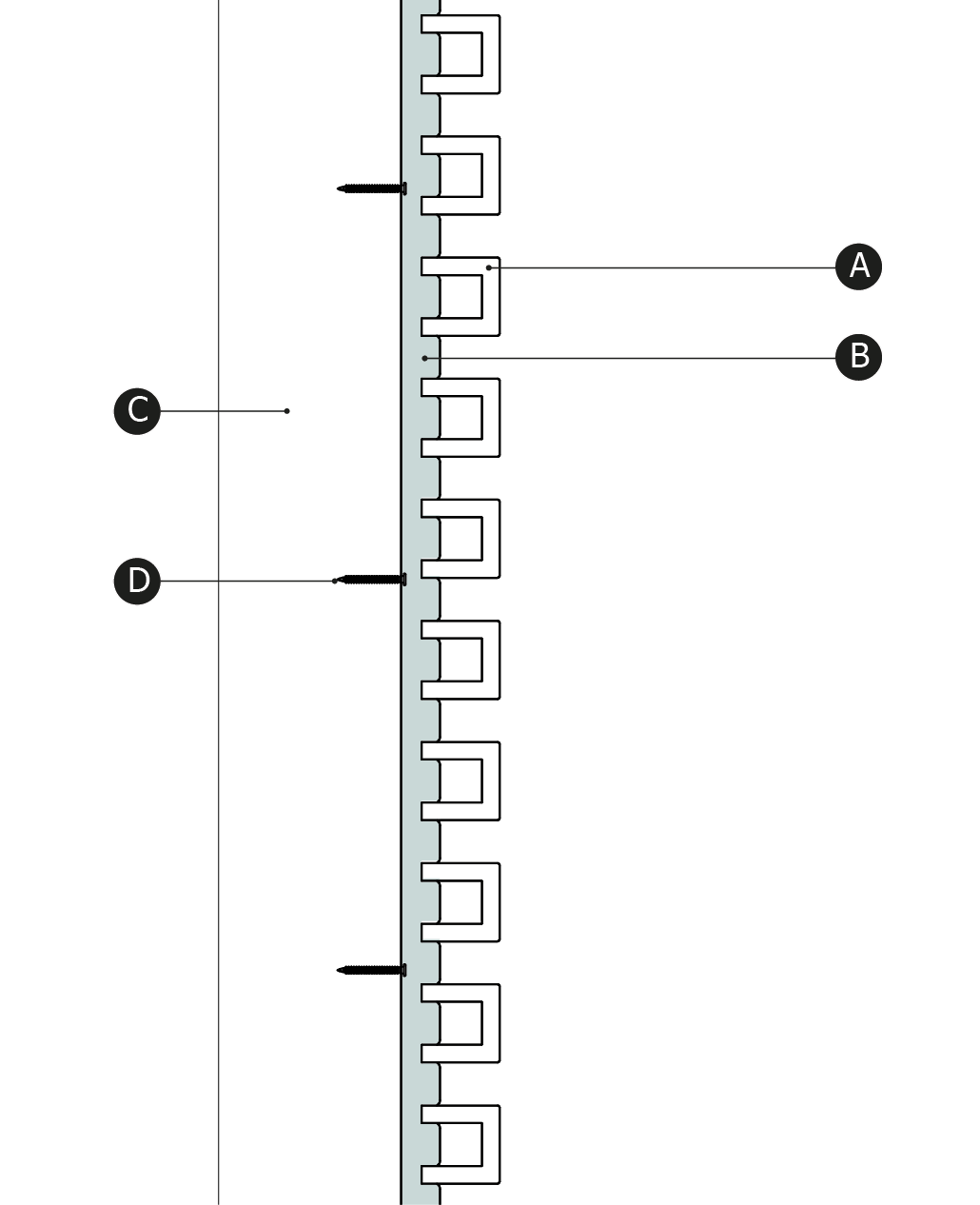

D. Nano absorbers (Nano + Helmholtz)

Nano absorbers are used to reduce mid to medium high frequencies. Nano absorbers work according to the Helmholtz mechanism, but do not need the traditional “chamber” (the void) to absorb sound. Sound energy is already transformed into heat energy when sound is penetrating the extremely narrow Helmholtz “neck” (2) formed by the Nano perforation holes (300.000/m²) with a diameter of only 0,5 mm. The sound absorption will although improve when an additional Helmholtz “chamber” (5) is added to the panel core behind the Nano perforated layer and when an air permeable felt (3) is applied to the back of the panel. When installed with a distance to the wall or ceiling, preferable filled with a porous mineral wool (1), the sound absorption will increase once again. When installed as described above, Nano solutions will combine several acoustic mechanisms leading to an outstanding absorption class B.

RECOMMENDED GUSTAFS PRODUCTS

Panel Nano

E. Porous absorbers

Porous absorbers are normally made of mineral or polyester wool (1) covered by a highly air permeable layer, for example a fabric (6). Porous absorbers are good in reducing high frequencies. Sound energy is transformed into heat energy while penetrating the wool twice, in and out. The sound absorption increases if the distance to the wall, and by that the total void is enlarged.

RECOMENDED GUSTAFS PRODUCT

Feltfon