Does non-combustible wood exists?

No, because wood is an organic and flammable material. So, how do we achieve a non-combustible wooden panel with fire classification A2-s1,d0? Compared to the A1 classification, the non-combustible classification A2-s1,d0 allows a content of a very low and restricted calorific value, measured in MJ/kg or MJ/m². A non-combustible fibre gypsum core plus a thin surface layer, for example a real wood veneer, can still can achieve classification A2-s1,d0.

– But a non-combustible core with a real wood veneered surface, can achieve classification A2-s1,d0.

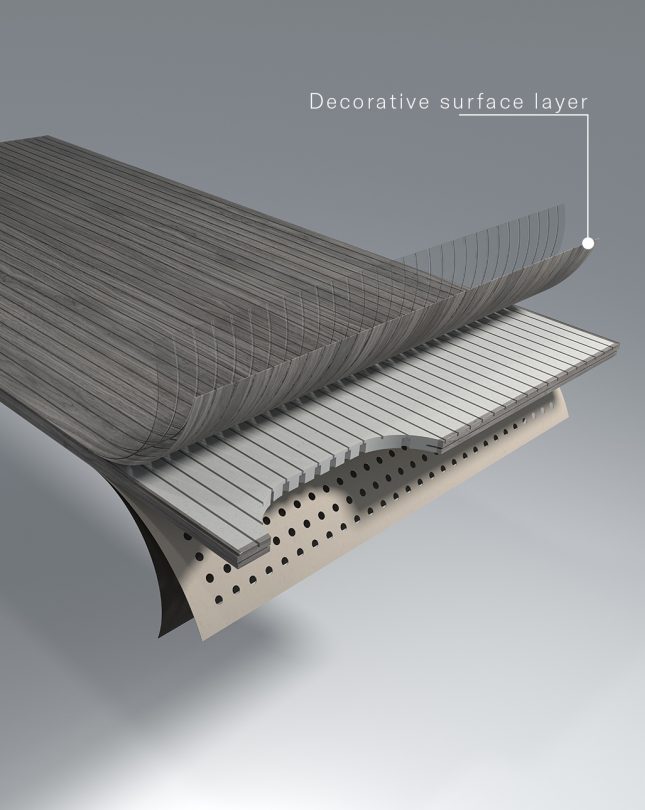

To meet the official fire regulations, the following four issues must be taken in regard:

1. A valid fire classification must include the decorative surface layer

Gustafs products are always tested and classified as they are used in real life, including the decorative surface, like a wooden veneer, an HPL or CPL laminate.

Some other suppliers claim to sell a fire rated board to which a surface material can be added. But the added surface material will drop the fire rating of the whole product to a “non-accepted” level.

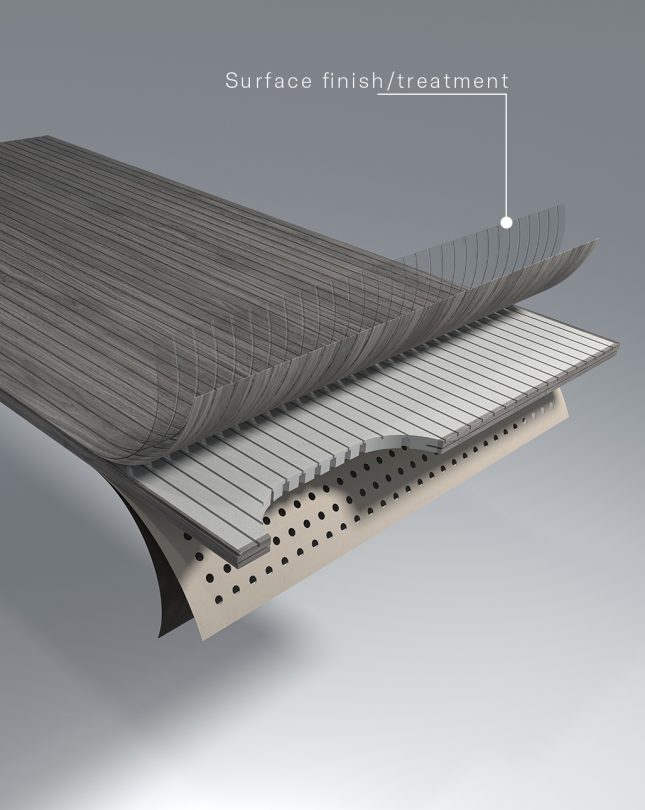

2. A valid fire classification must include the surface finish/treatment.

Gustafs products are always tested and classified as the are used in real life, including the final surface treatment like a lacquer, paint, oil or stain.

Some other suppliers claim to sell a fire rated board to which a surface finish can be added. But the added surface treatment will drop the fire rating of the whole product to a “non-accepted” level.

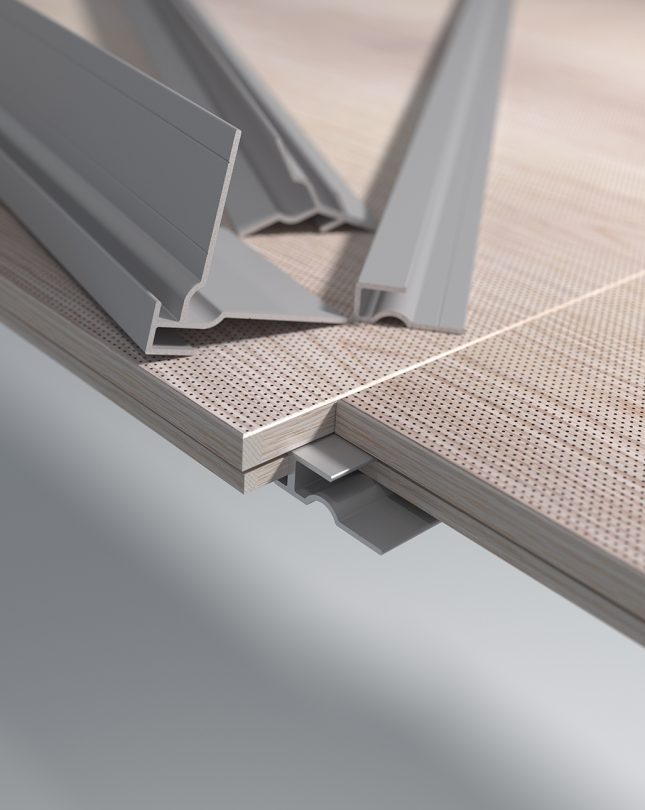

3. A valid fire classification must include the installation construction.

Gustafs products are always tested and classified as the are used in real life, including the installation with information about the fixing system, the air void, open or closed joints, etc.

Some other suppliers will sell solutions with fire classifications related to the raw material board only, a board that has not been tested as finally installed and by that not confirm the practiced installation.

4. A valid fire classification must include factory post treatments

First of all: on-site post-treatments can not be classified at all. Gustafs products are always tested and classified as they are used in real life, including for example the acoustic perforations or when we cut core materials into Linear solutions.

Once again, it is always the final Gustafs solution that has been classified. Some other suppliers will sell solutions with fire classifications for the raw material board, without the acoustic perforations included in the actual test, or without having tested the material sawn into Linear timber.