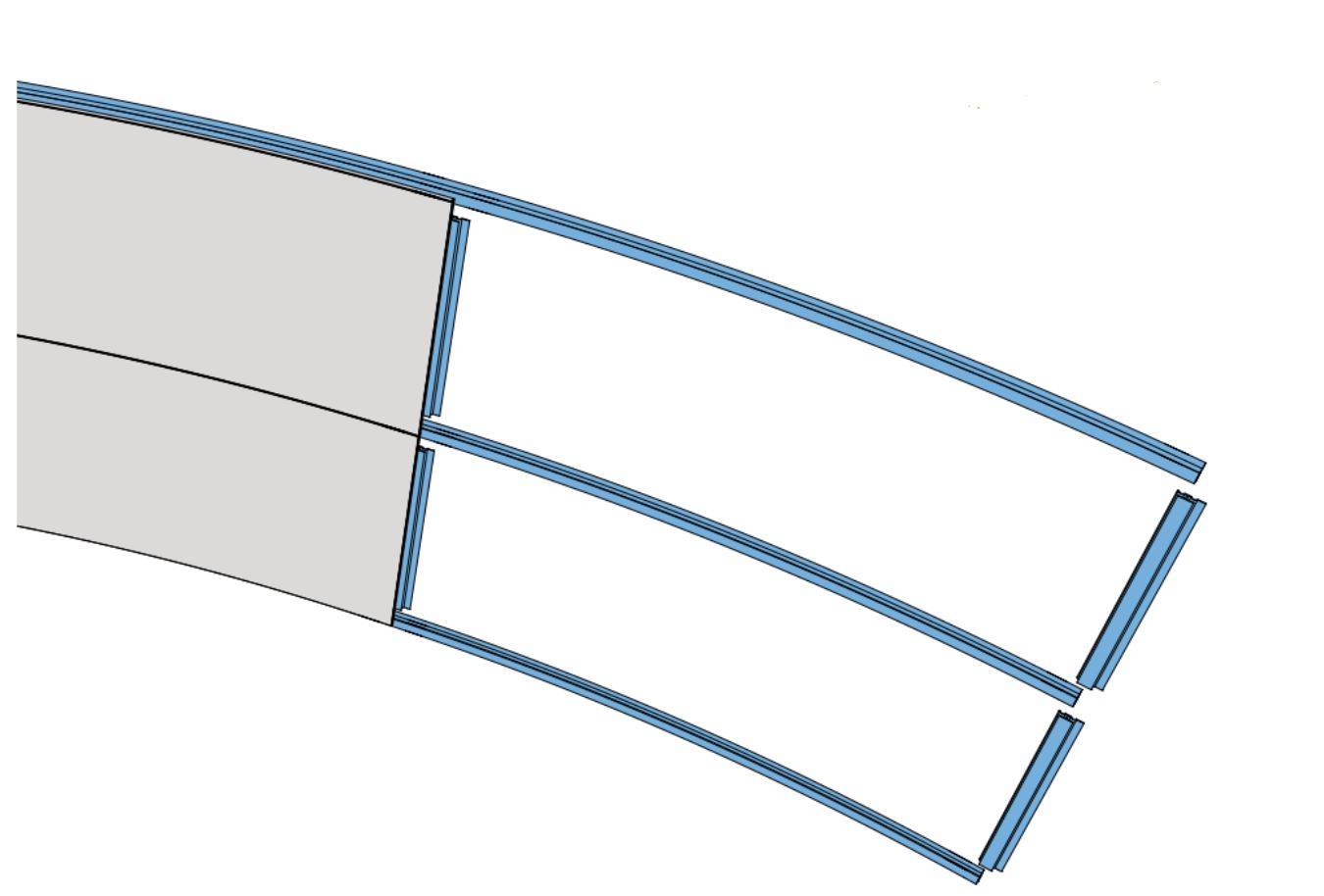

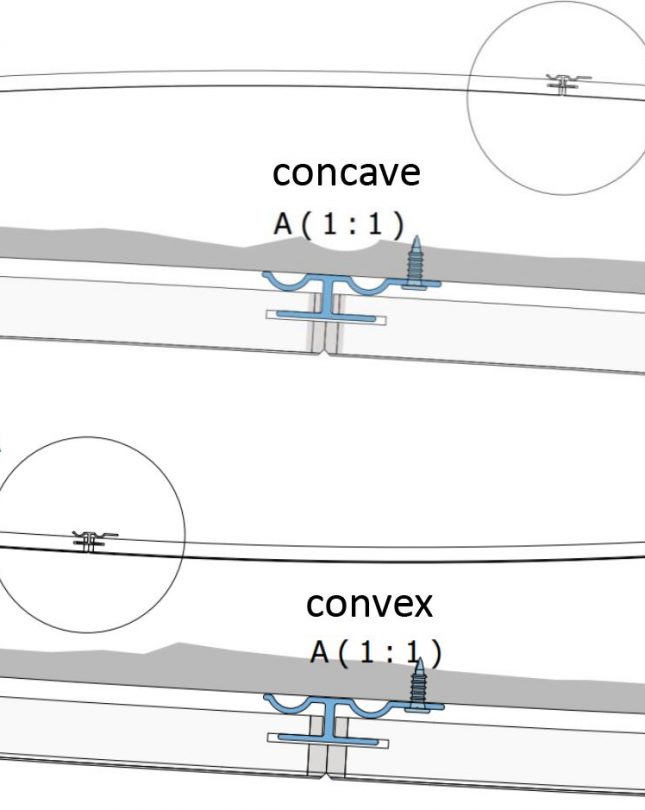

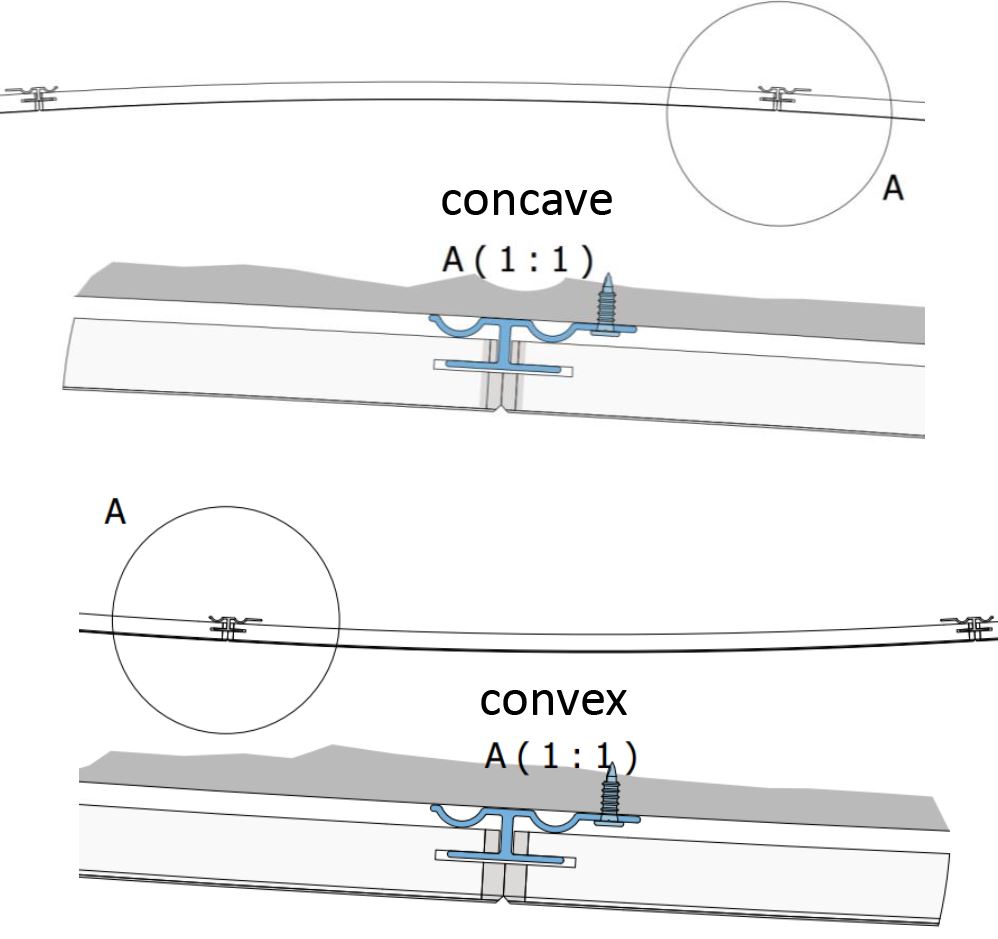

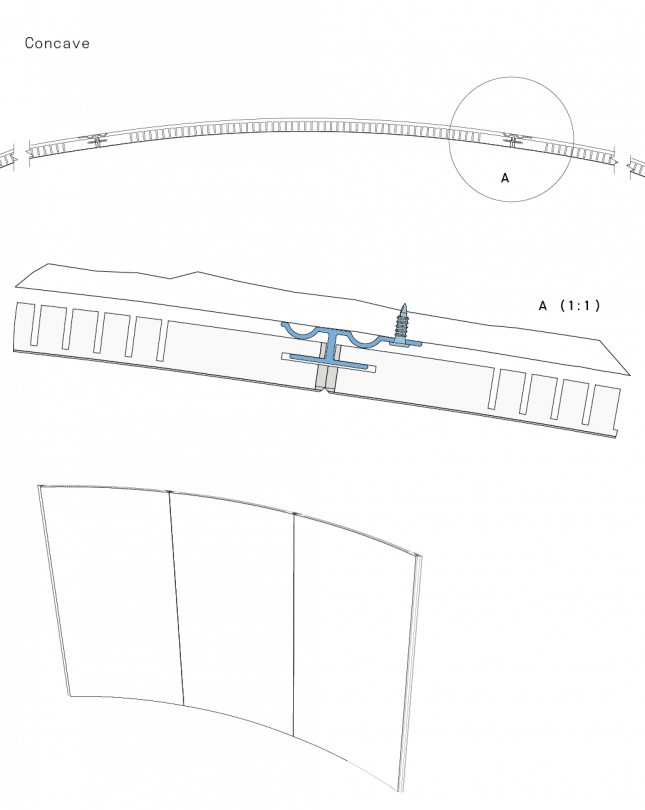

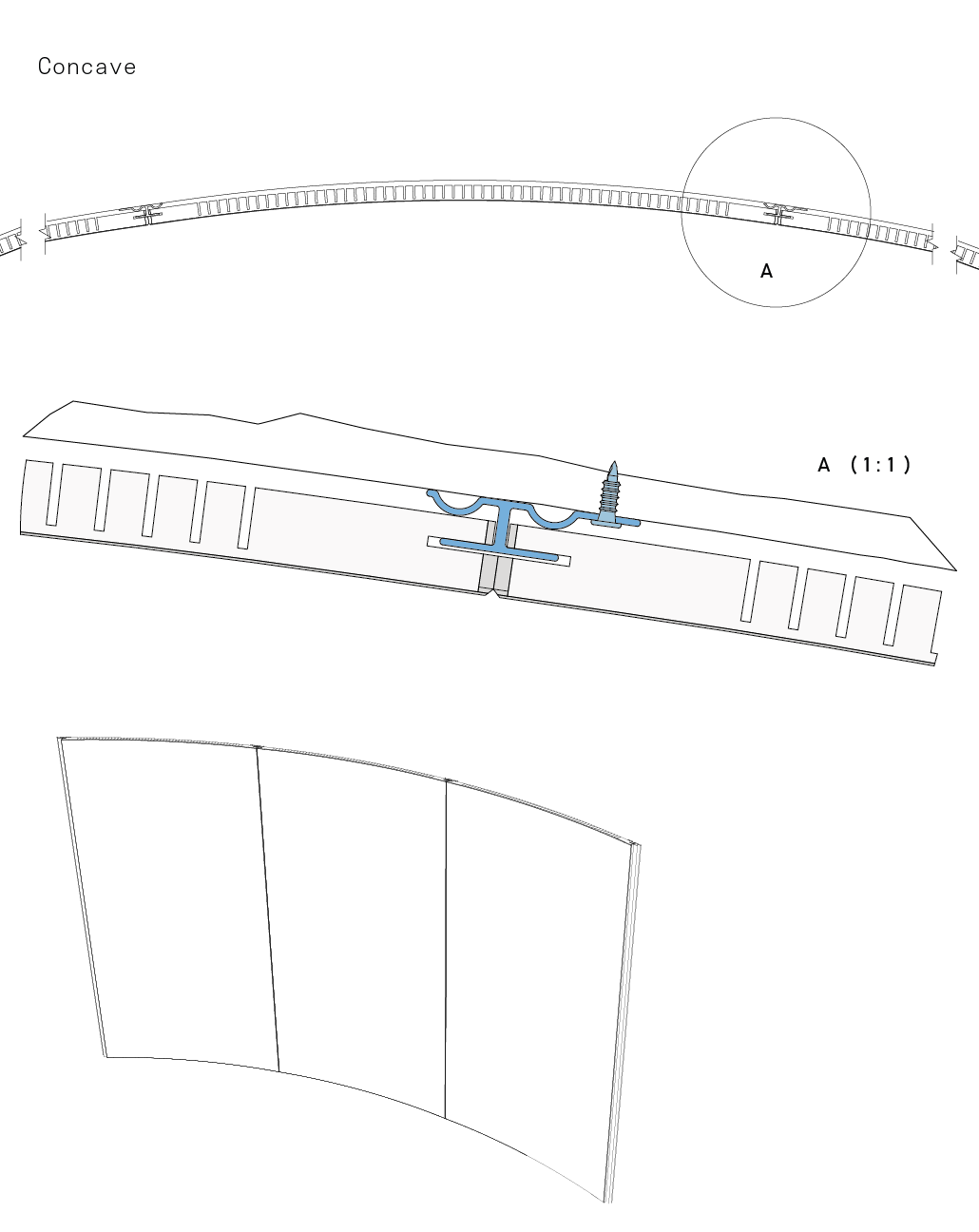

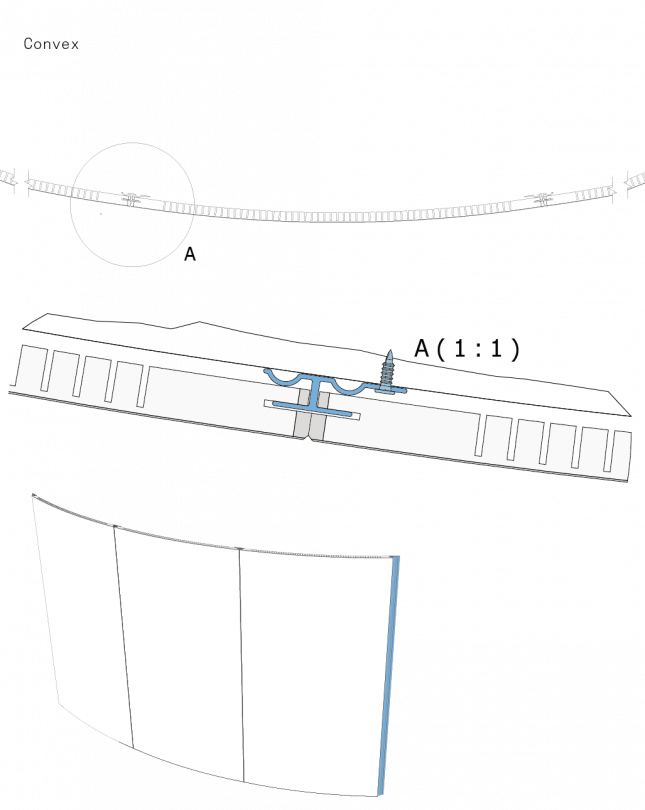

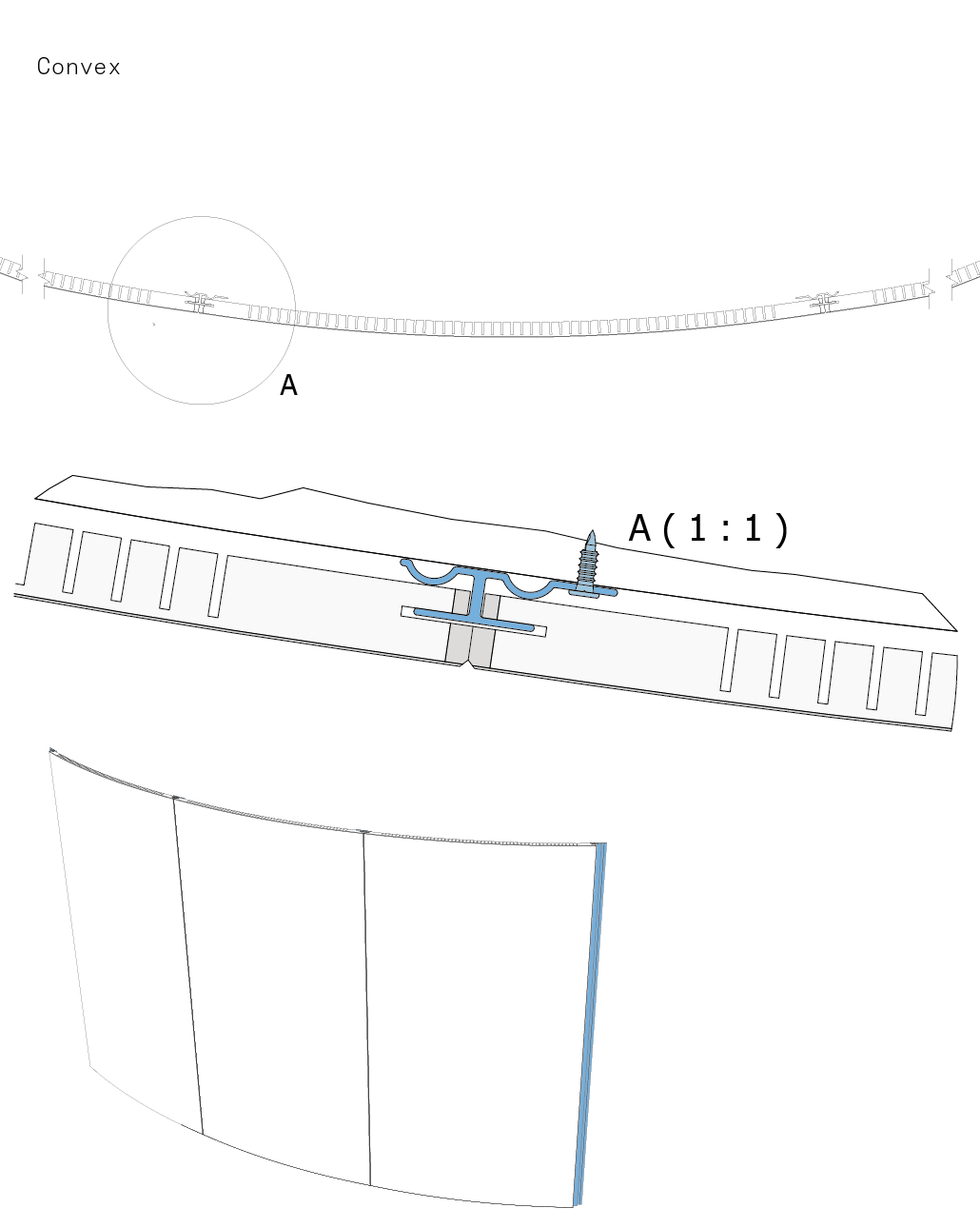

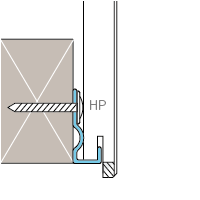

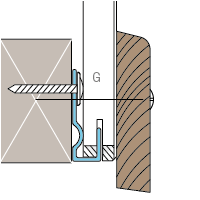

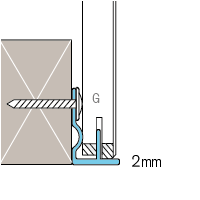

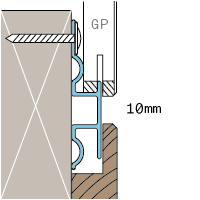

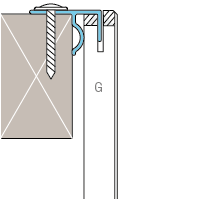

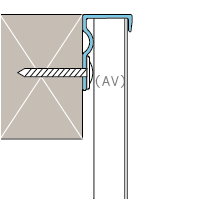

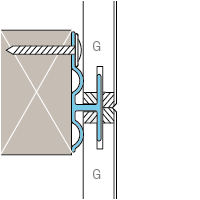

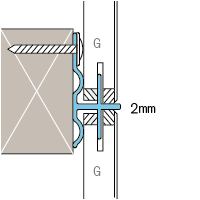

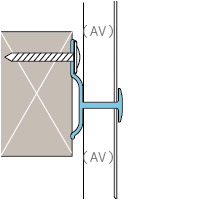

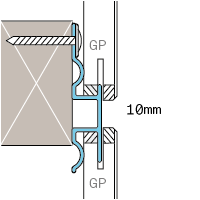

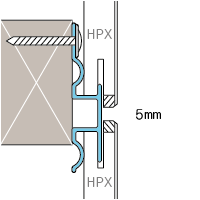

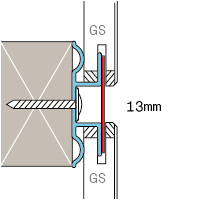

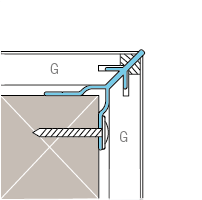

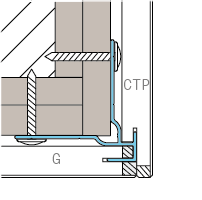

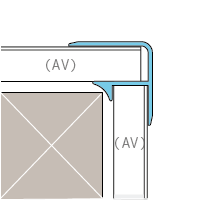

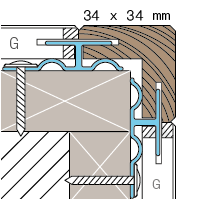

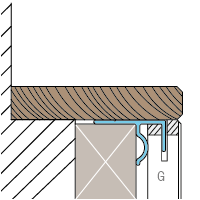

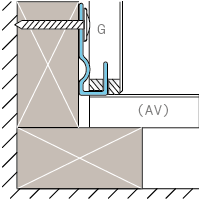

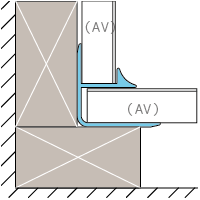

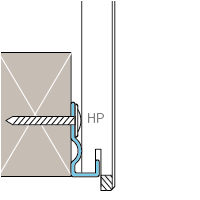

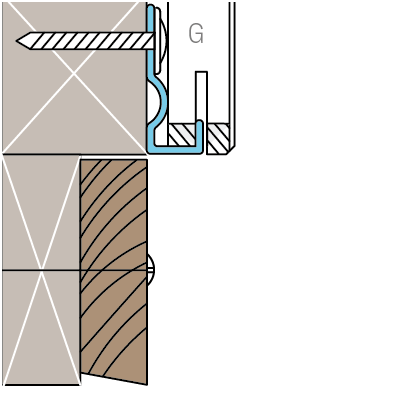

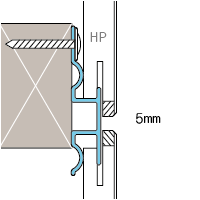

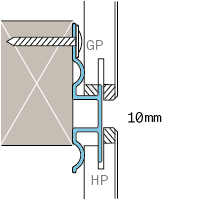

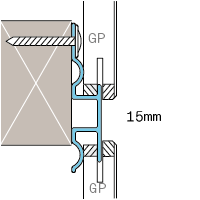

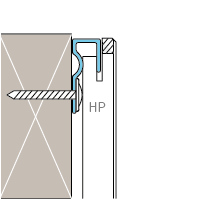

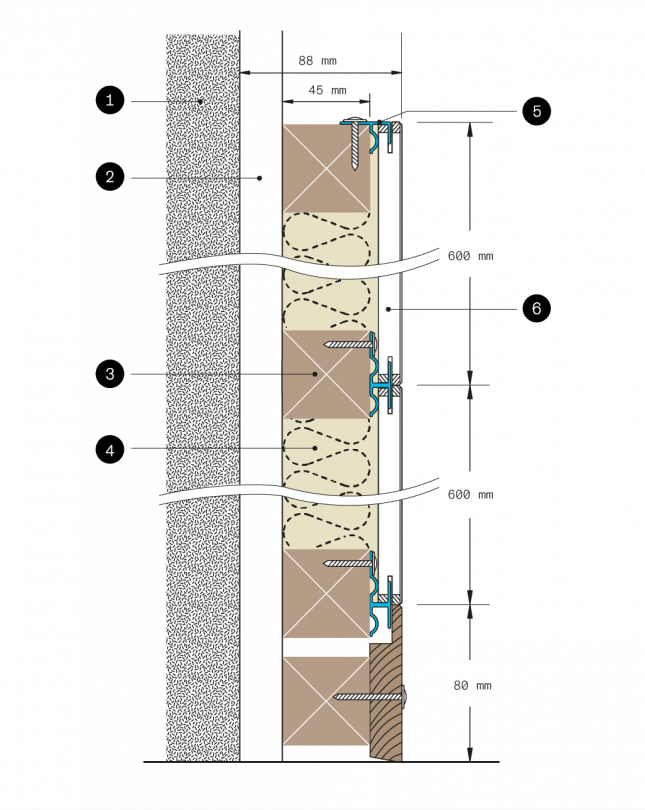

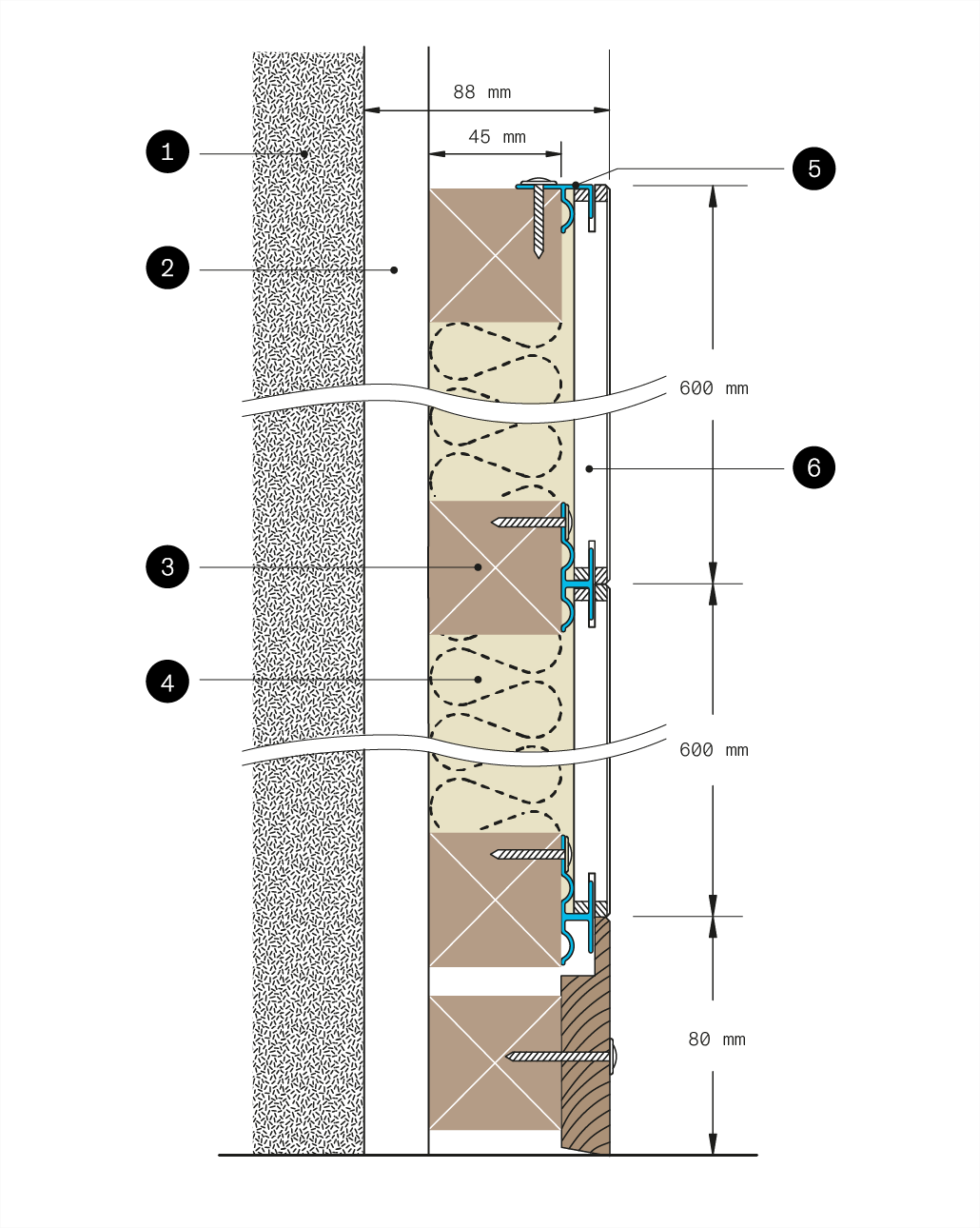

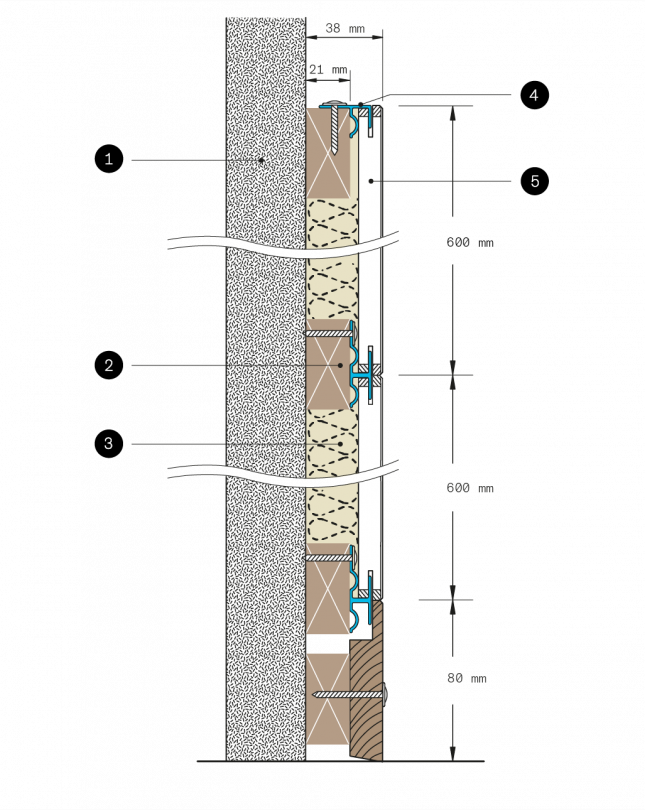

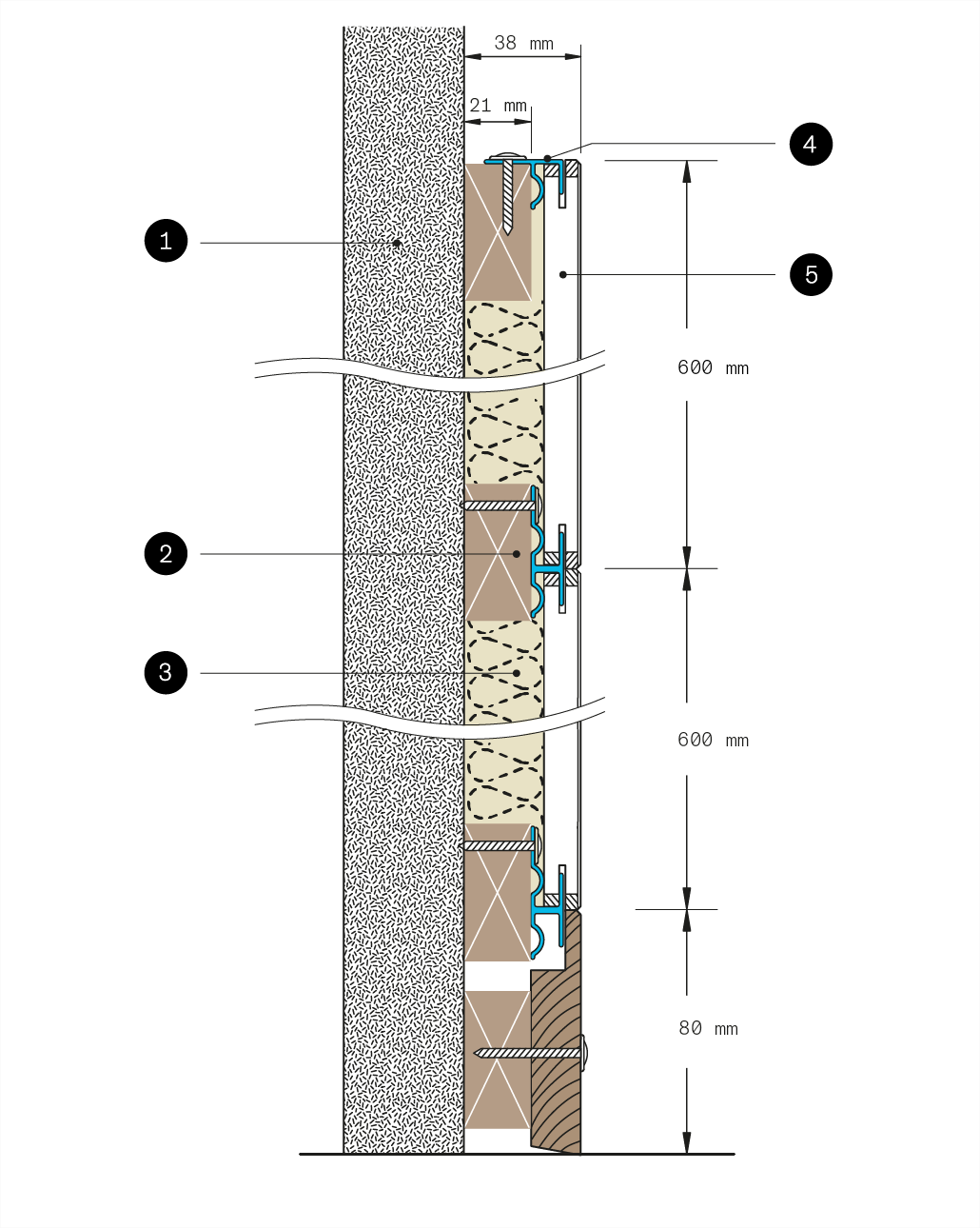

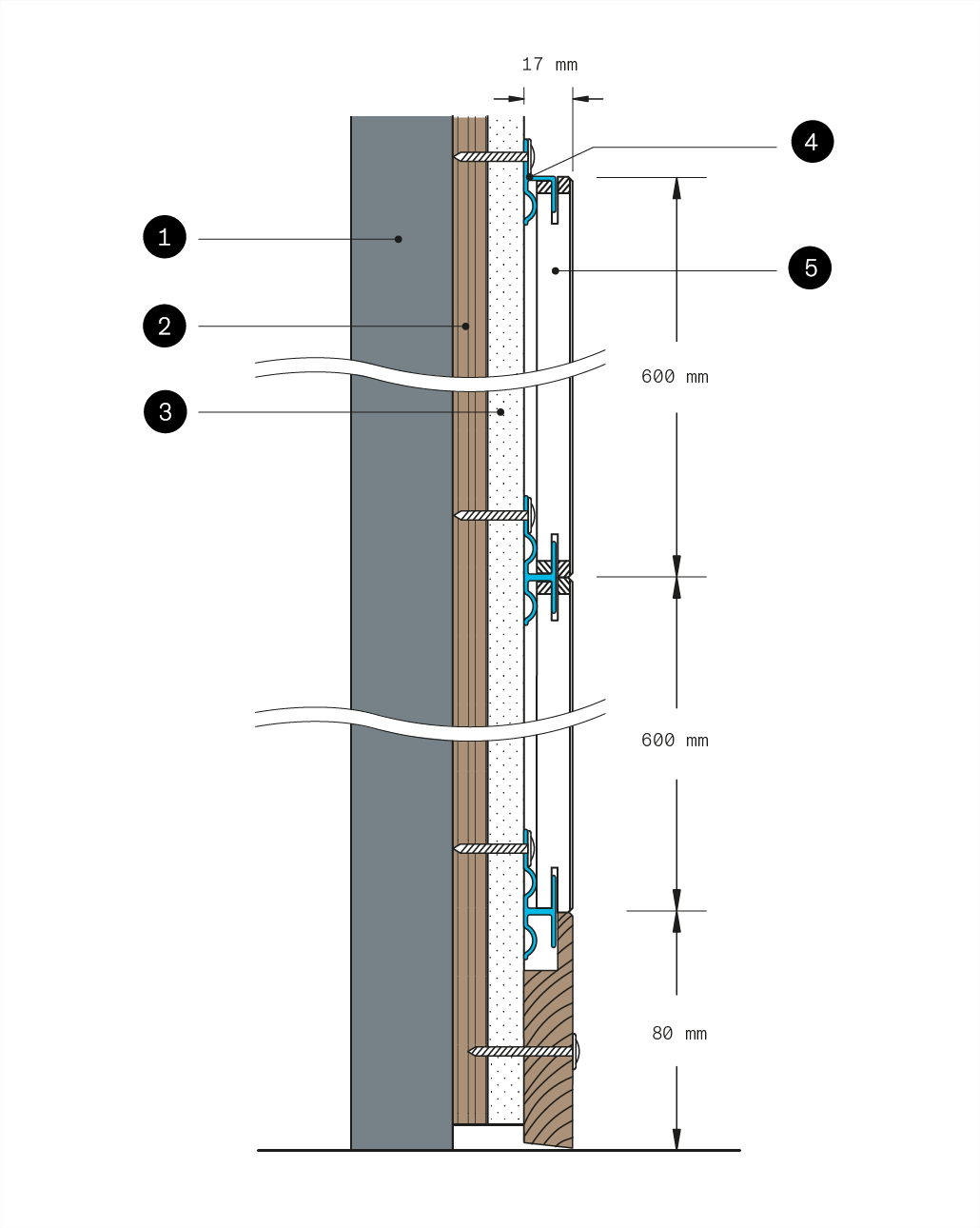

Gustafs Panel System is fitted on to walls by means of Capax mounting profiles so that each panel is individually locked on all four sides. The Capax installation system is fully integrated with the panels, concealed, time saving and reliable.

Panel Installation – Wall

Gustafs Panel System is fitted on to walls by means of Capax mounting profiles so that each panel is individually locked on all four sides. The Capax installation system is fully integral with the panels, concealed, time saving and reliable.