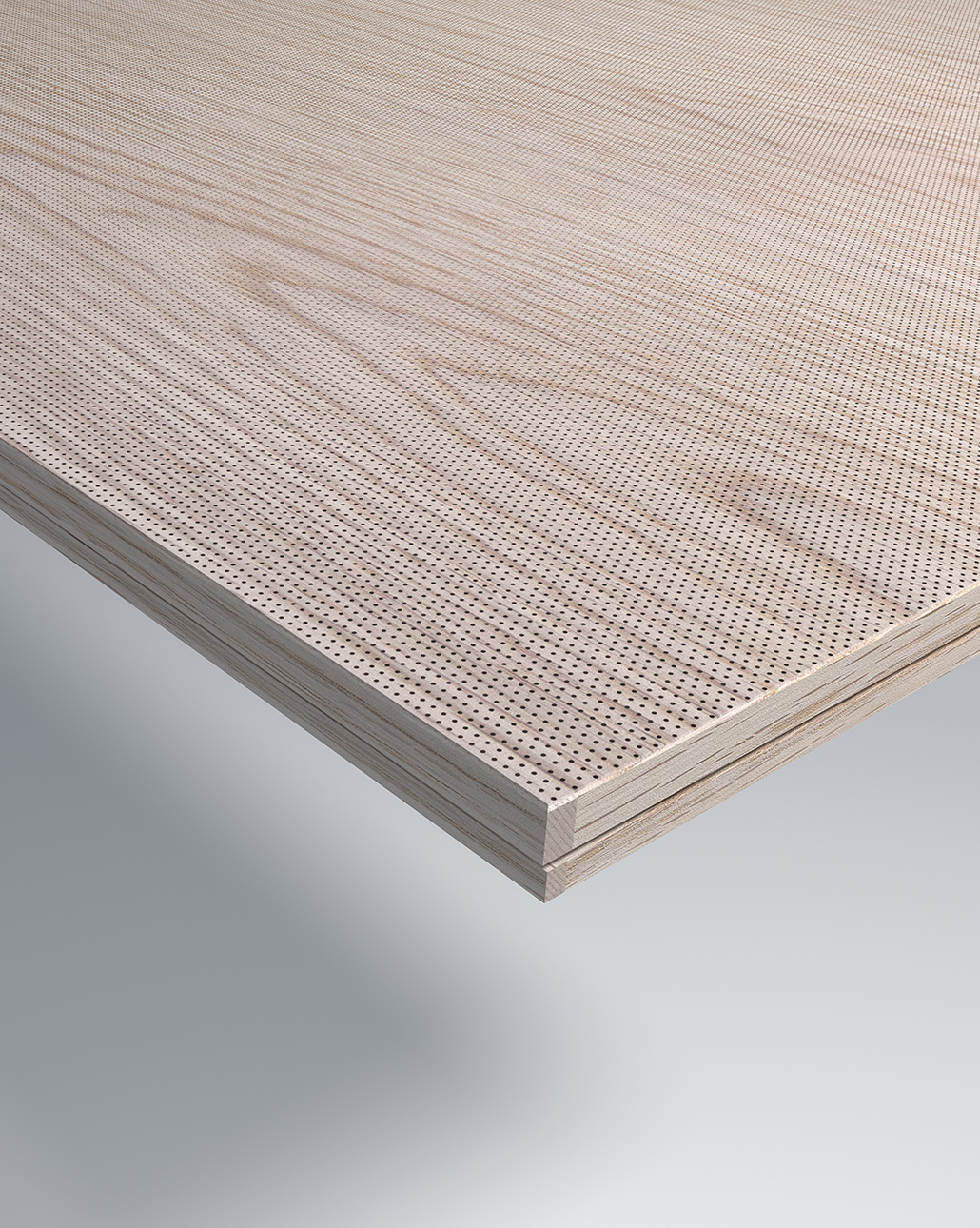

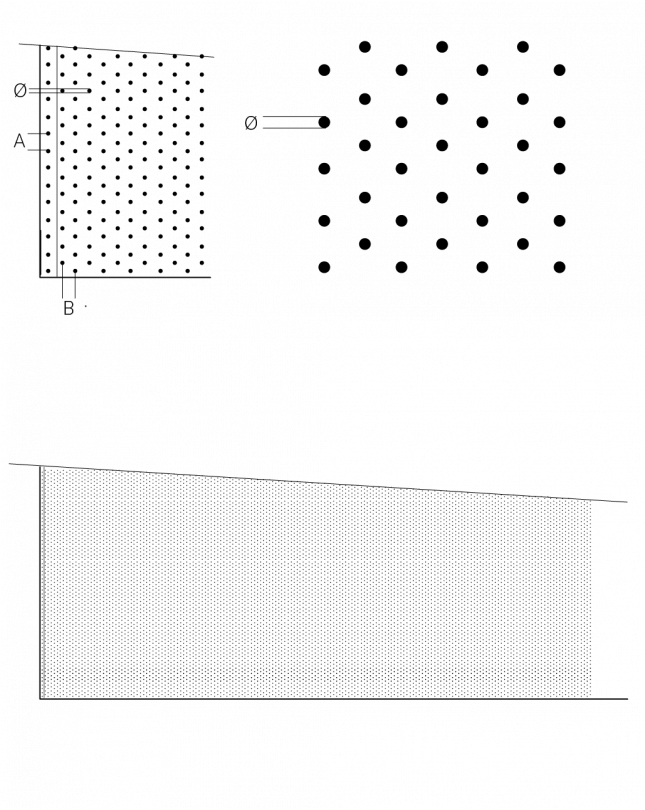

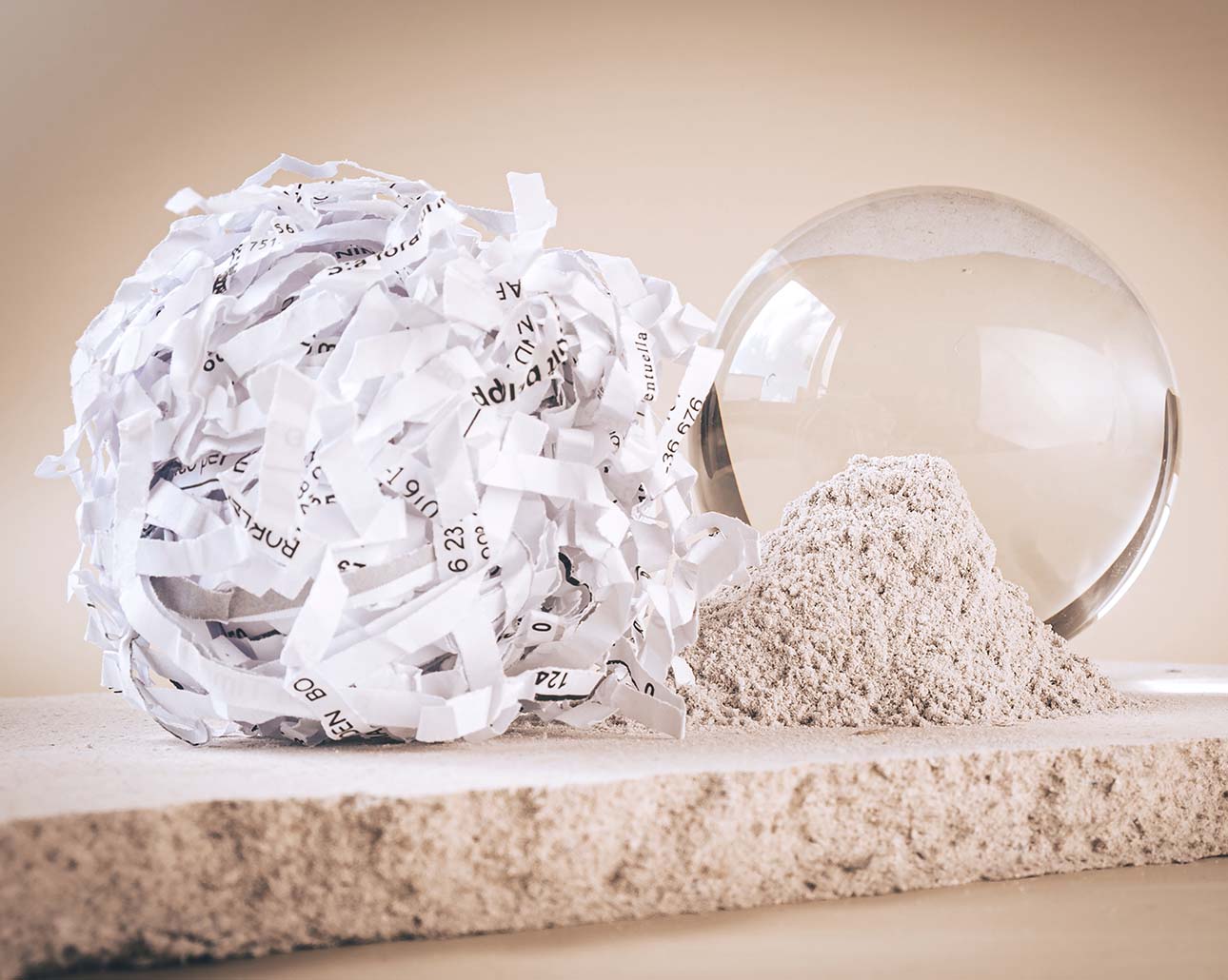

The almost invisible perforation gives you a wood panel contributing to perfect acoustics with a homogeneous look suitable for both walls and ceilings.

Acoustic Panel Nano

MICRO PERFORATED PANELS FOR WALLS AND CEILINGS

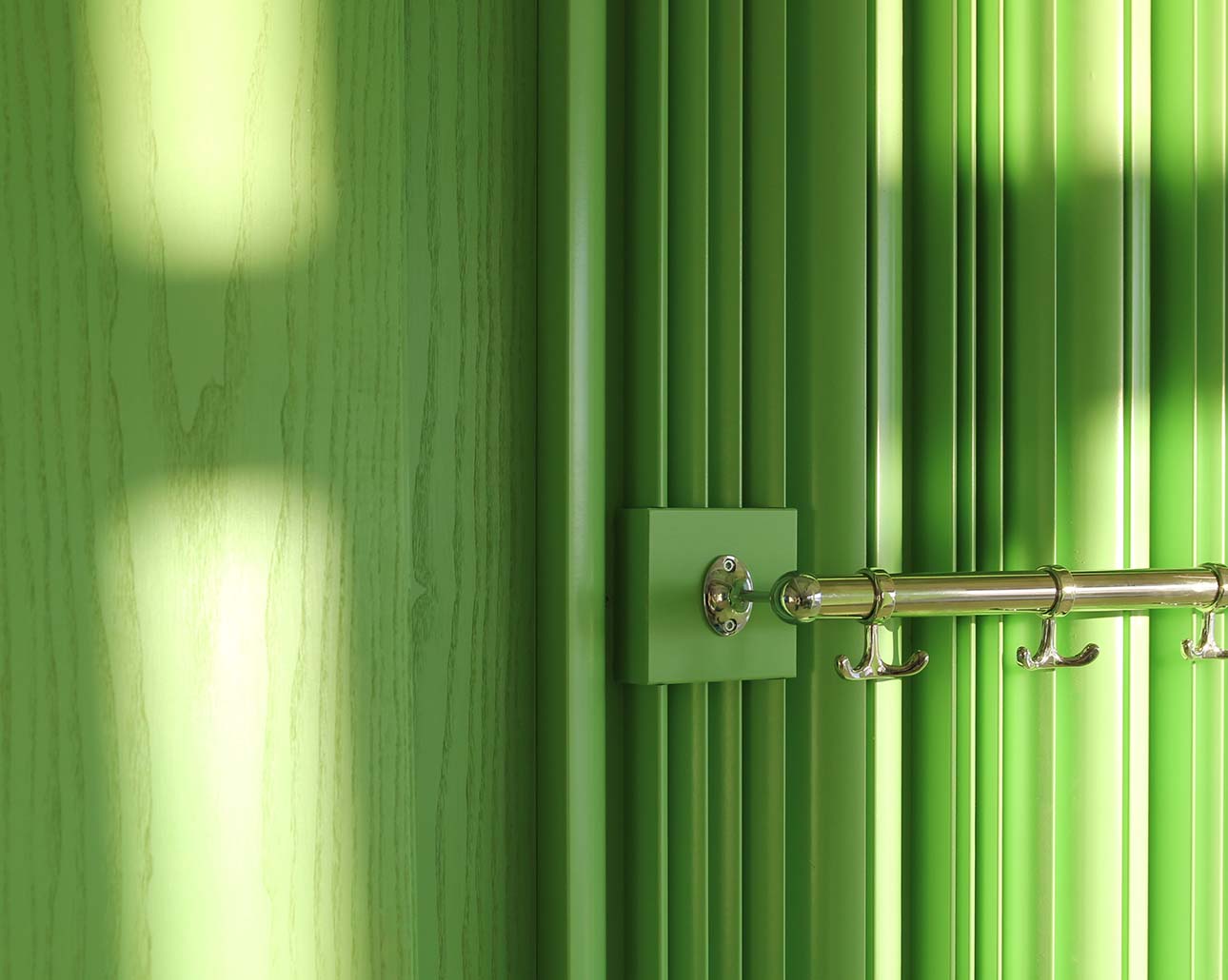

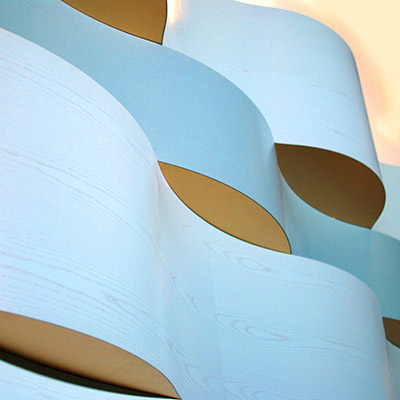

From a normal viewing distance, the Nano perforation is invisible, but the acoustic qualities are excellent with absorption class A (αw 0,90). Gustafs Nano is less depending on insulation and air gaps behind the panel, so in general thinner walls and ceilings can be achieved, saving valuable space. Depending on the wood specie, the type of veneer cut, the pigmentation and ultimately the installation pattern, a wooden Nano panel brings nature in-door. Our acoustic panels are installed with Gustafs famous Capax system for a beautiful end-result.